|

Brewing The Brewing Process |

||||

| Brewing is one of the oldest industries in the country, and as one would expect of such a traditional industry, the principles of creating beer has changed very little as the centuries have passed. Today brewing has crystallized into a number of distinct steps: | ||||

| The Grist For each individually brewed ale different types and varieties of malted barley are used, in different proportions, to make up the recipe. Roasted barley, chocolate and black malts are used in the darker beers, while amber, crystal and malted wheat is used in the lighter ones. Examples are shown on the barrel below. |

||||

The lion’s share of any grist is the malted barley, from where most of the sugars come from. The lion’s share of any grist is the malted barley, from where most of the sugars come from. |

||||

| Grist to the Mill Once the malts have been carefully weighed and counted they are then loaded into the mill, where they are cracked. They are then stored in the grist case awaiting the next day's brewing. The expression "it's all grist to the mill" derives from this operation. |

||||

|

The Run off The sugar is extracted by adding water to the “Mash Tun” and boiled for one or two hours to a temperature of around 15ºF. The crushed malted barley is then added and the liquid is then strained through the bottom of the tun and is sprayed with hot liquor (Sparged) to extract the goodness. The hot sweet liquid (Wort) then runs off, by gravity, into the under-back, where it is then pumped into the copper (Kettle). |

|||

The Copper (Kettle) |

||||

Casting |

|

|||

|

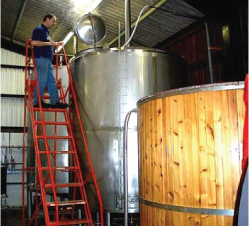

Fermentation Depending on what’s brewing the fermentation lasts for about two to three days, yeast is then skimmed for the next brew and when the correct strength is reached the beer is then cooled for a further four days before being racked in casks. The ale is then cooled to 43oF. |

|||

| Yeast is a living organism which converts sugar into alcohol. It forms on top of the brew, being skimmed off before racking A small amount of sugar is left un-fermented at this stage to allow the beer to secondary ferment in the cask. Hence the name "cask conditioned beer". |

||||

| Racking & Storage Beer is then racked, (which means being transferred to the casks in which it is sold to pubs), at which point isinglass finings are added to clarify the beer. The casks of beer are then stored for seven to ten days in the refrigerated beer store before being distributed to the trade. This allows the beer to condition and mature. |

|

|||

|

Monitoring Quality

|

|||

|

||||